Have you ever wished you could bypass the step of applying moisturizer post-shower, but without skimping on skin hydration? The latest trend in skin care, in-shower moisturizers, might be your magic elixir.

Infused with cutting-edge technologies and new-fangled machinery, these products promise to deliver quick, potent hydration while you shower. Dive into the world of in-shower moisturizers, as we unravel their science and explore the fascinating innovations behind them.

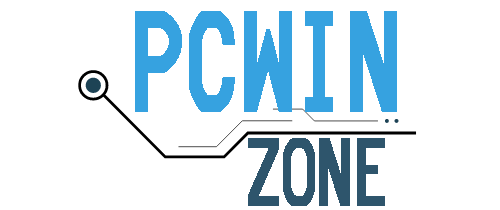

Automated Mixing and Emulsification Systems: Homogenizing Ingredients

Harnessing the power of automation, manufacturers have upgraded their formula crafting techniques. Automated mixing and emulsification systems blend myriad ingredients into a harmonious mixture. Through these technologies, inconsistent or lumpy textures, which can compromise absorption, are vanquished.

Emulsification doesn’t just mix; it unites water and oil-based ingredients into a seamless blend. It’s pivotal for ensuring the product’s potency remains consistent. Without proper homogenization, you could be missing out on the full suite of benefits the best in shower moisturizers promise.

Precision Dispensing Machinery: Ensuring Accurate Ingredient Ratios

Accuracy in dispensing ingredients is non-negotiable. A slight misstep could change the moisturizer’s efficacy or, worse, lead to skin irritations. Precision dispensing machines take the guesswork out of the equation. With impeccable precision, they guarantee the right proportion of each ingredient in every batch.

As you drench your skin with your preferred moisturizer, remember this meticulous process. It ensures that the hydration, fragrance, and therapeutic properties are consistent, giving you that refreshing feel each time.

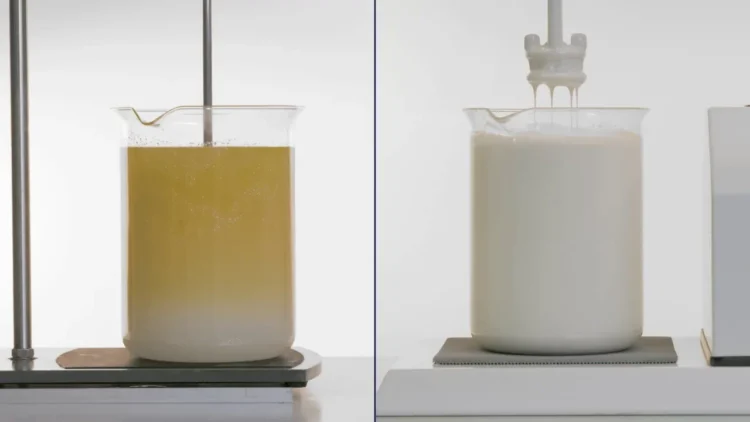

High-Pressure Homogenizers: Achieving Uniform Particle Size and Texture

Ever noticed how some moisturizers feel silkier than others? Thank high-pressure homogenizers for that. These machines break down particles into smaller, uniform sizes, creating a texture that’s both rich and easily absorbable. The magic lies in using intense pressure to force the mixture through narrow spaces, refining its consistency.

When particles are uniform, the moisturizer spreads evenly, ensuring every inch of your skin gets its fair share of hydration. This process guarantees the ultimate pampering experience during your quick shower sessions.

Innovations in Emulsion Stability Testing: Enhancing Shelf Life

A product’s shelf life isn’t just about longevity; it impacts efficacy. Through emulsion stability testing, brands can determine how long a moisturizer retains its potency. The latest innovations in this arena involve microscopic analysis and advanced computational modeling, predicting how formulas will behave over time.

Such rigorous testing has dual benefits. Not only does it guarantee you’re applying an effective product each time, but it also means less waste. With extended shelf life, you have more time to use the product to its last drop.

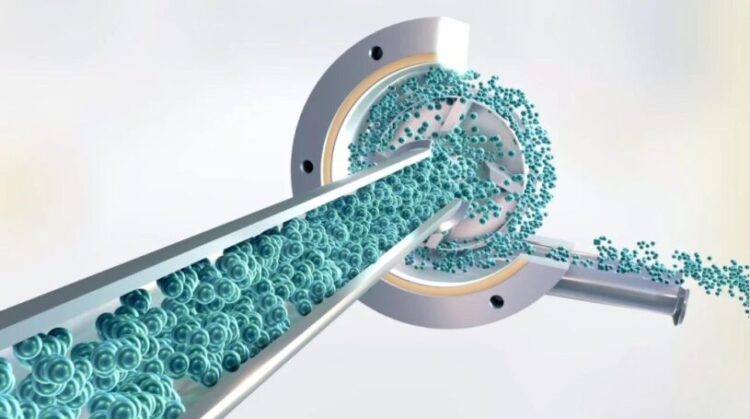

Microfluidics Applications: Optimizing Ingredient Dispersion

Microfluidics has revolutionized the realm of in-shower moisturizers. This technology manipulates tiny volumes of fluids, achieving optimal ingredient dispersion. At this microscopic level, manufacturers can ensure that every drop of moisturizer packs a punch.

Beyond potency, there’s an aesthetic delight in using products refined with microfluidics. These moisturizers feel lighter, yet more potent, making your in-shower hydration ritual nothing short of luxurious.

Advanced Heating and Cooling Units: Controlled Temperature Formulation

Temperature can make or break a product’s formulation. Advanced heating and cooling units now play a pivotal role in the production process. By carefully controlling the temperature, these units ensure that ingredients meld together perfectly without degrading their individual properties.

So, each time you slather on that in-shower moisturizer, recall the meticulous temperature-controlled process behind its creation. It’s this precision that gives the product its unique consistency and unparalleled hydrating properties.

Ultrasonic Processing: Breaking Down Ingredients for Enhanced Absorption

Sound waves, especially ultrasonic ones, possess transformative powers in the world of moisturizers. Ultrasonic processing uses these waves to break down ingredients into minuscule particles, enhancing their absorption potential. This technique ensures that the skin benefits from every active ingredient in the formula.

You can think of it as fine-tuning your moisturizer to ensure maximum penetration. This not only guarantees hydration but also ensures that other therapeutic ingredients reach deeper skin layers.

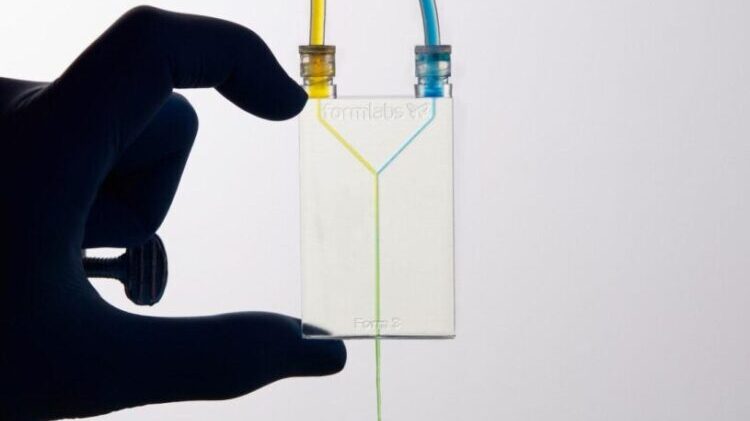

Nanoencapsulation Techniques: Delivering Active Ingredients Deeper into the Skin

Imagine wrapping active ingredients in tiny capsules that can traverse the skin’s barrier. That’s nanoencapsulation for you. By enclosing ingredients in nanometer-sized vesicles, they’re delivered deeper, optimizing their beneficial impacts.

The sensation of these moisturizers is distinctive. They feel light yet intensely hydrating, a testament to the deep-reaching prowess of the encapsulated ingredients.

Spray Technology: Creating Even Application and Coverage

The final flourish in crafting the perfect in-shower moisturizer is ensuring its impeccable application. Spray technology has made strides in this aspect. Modern sprayers disperse the product evenly, ensuring that every part of your body gets an equal hydration opportunity.

This technology doesn’t just ensure thorough coverage; it elevates the experience. The misty application feels refreshing, turning your speedy hydration routine into a spa-like treat.

In-Line Quality Monitoring: Real-time Assessment for Consistency

The essence of an ideal moisturizer isn’t just about the final product but the journey of its creation. In-line quality monitoring systems have transformed this journey, offering real-time insights into product consistency during the manufacturing process. These systems use advanced sensors and analytics to detect minute variations in formula composition.

If there’s any deviation, alerts are instantly generated, ensuring that only top-notch products move to the next stage. Such rigorous, real-time oversight is indispensable. It guarantees that every bottle of in-shower moisturizer you pick up holds the promise of unmatched quality and hydration.

Smart Packaging Integration: Touchless Dispensing and Dosage Control

The marvels of in-shower moisturizers aren’t just confined to their formula; their packaging is equally ingenious. Smart packaging now features touchless dispensing mechanisms, ensuring optimal hygiene and minimizing contamination risks. Imagine a seamless wave of your hand, releasing the perfect amount of moisturizer.

This magic is further enhanced by built-in dosage control. No more guesswork or overuse; these containers deliver just the right amount for optimal skin hydration. Such innovations not only elevate the user experience but also champion sustainability by reducing product wastage.

Automated Filling and Sealing Equipment: Streamlining Production Processes

Behind every bottle of your favorite moisturizer lies an orchestra of machines working in perfect harmony. A maestro in this ensemble is the automated filling and sealing equipment. These machines have redefined efficiency, filling containers with exact amounts of product and then sealing them to ensure freshness.

The automation reduces human error, ensuring that every package is consistent in quantity and quality. Furthermore, it expedites the production process, ensuring that these hydrating wonders swiftly move from production lines to your bathroom shelves, ready to transform your hydration game.

Parting Thoughts

Our foray into the captivating realm of in-shower moisturizers underscores their scientific brilliance. These aren’t mere products; they’re masterpieces, crafted with precision and innovative technologies. As you embrace this hydration shortcut, remember the marvels behind each droplet. Here’s to quicker, smarter, and more luxurious hydration rituals!

We understand that your skin is essential, but your hair is equally important. Explore our article on technological advancements in the hair care industry to discover how you can use new technologies to maintain your hair’s health and vitality.